Khatavahi BI Solutions LLP - How Our Paper Plate Manufacturing ERP Automates Your Entire Production Process

Our ERP is an all-in-one solution that helps you manage: Raw material inventory, Carton Management, Barcode Scanning, Stock management and dispatch tracking, Accounting and billing

Paper Plate Manufacturing ERP

Complete Process & System Overview

Introduction

Managing a paper plate manufacturing unit manually can be chaotic — tracking raw materials, handling machines, managing labor, monitoring stock, and ensuring timely delivery often become overwhelming.

That’s where our Paper Plate Manufacturing ERP comes in.

Designed specifically for small and medium manufacturers, it automates the entire workflow — from raw material purchase to production, packaging, inventory management, and sales — all in one integrated system.

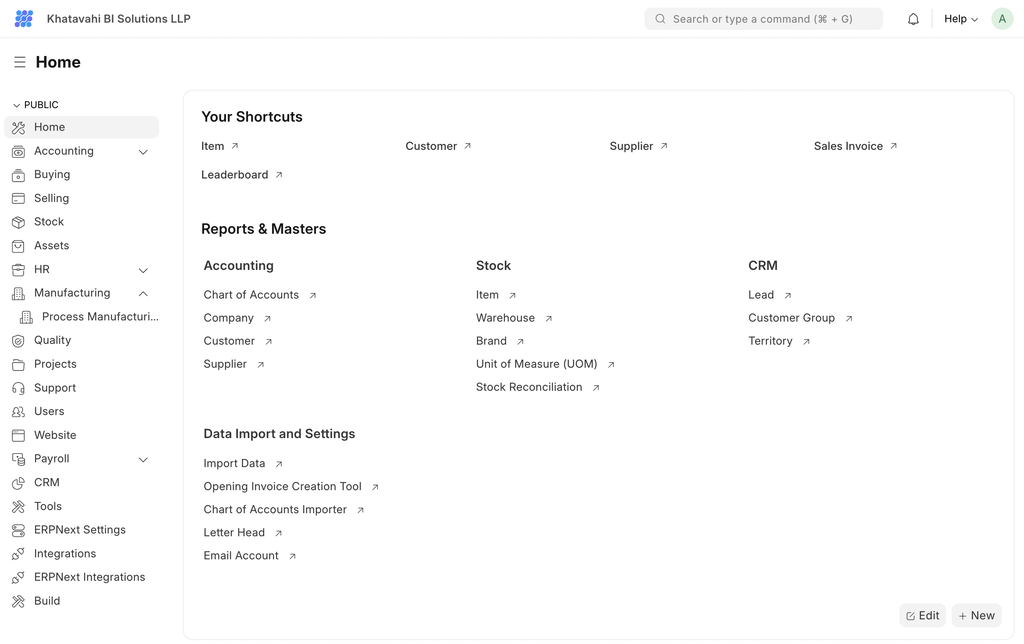

Dashboard

Our main dashboard gives you a bird’s-eye view of the entire factory’s performance, including stock, production, orders, and daily activity.

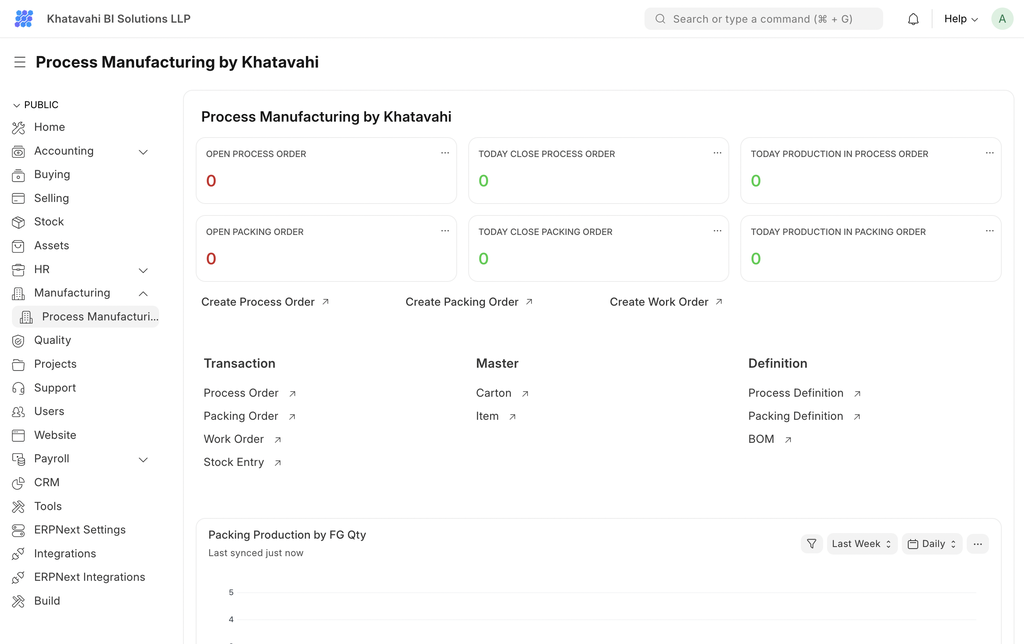

Manufacturing Dashboard

A dedicated manufacturing dashboard helps operators, supervisors, and owners track real-time production status, machine performance, and process orders.

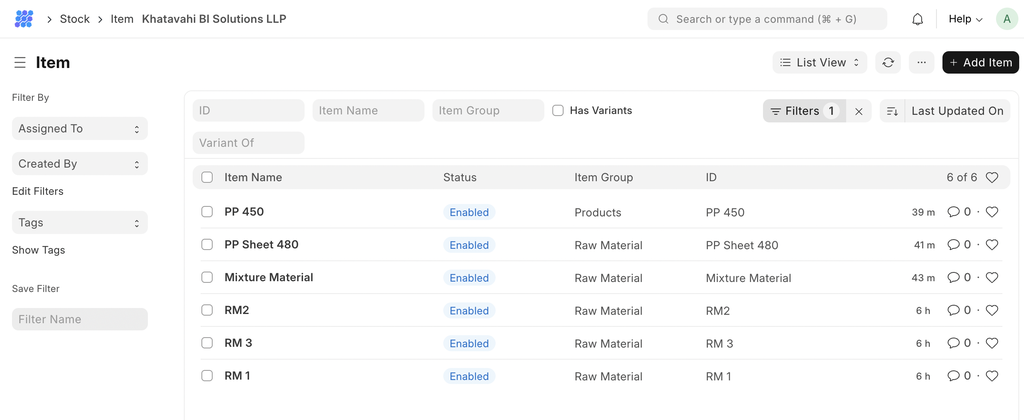

Item Master

The Item Master maintains detailed information about Raw Materials, Semi-Finished Goods, and Finished Products — ensuring complete data accuracy across all departments.

Reports

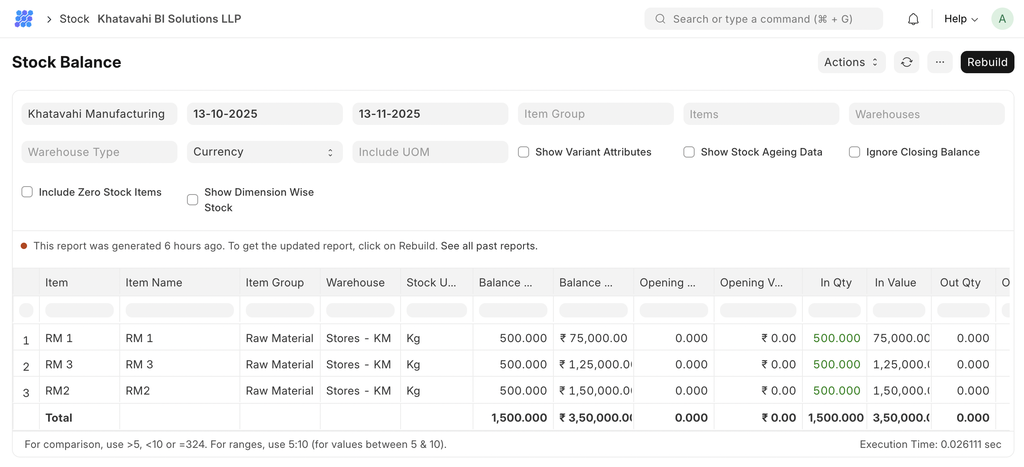

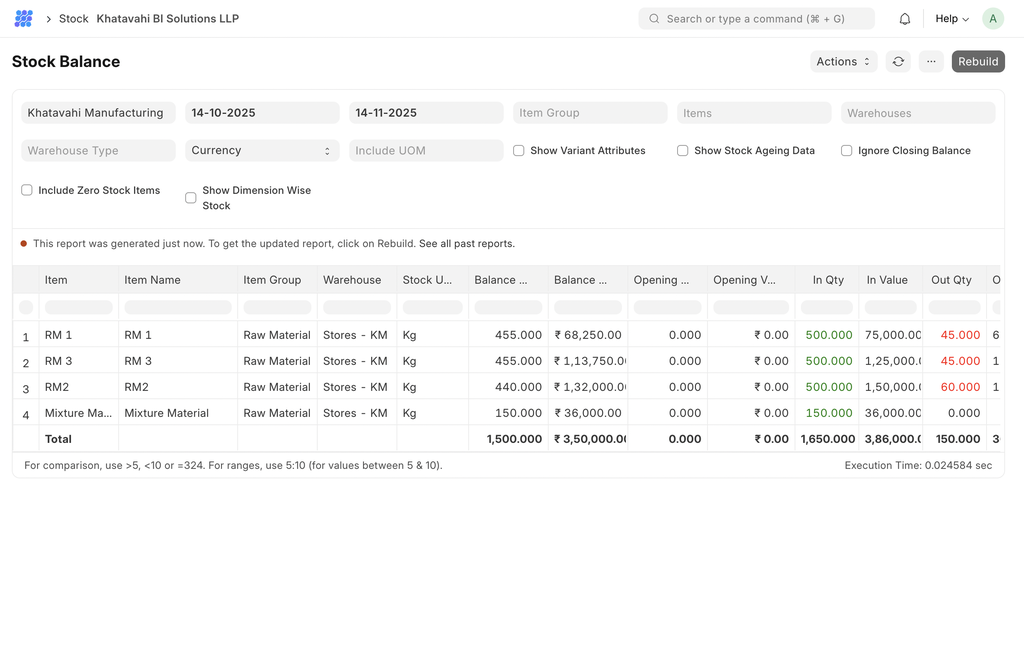

Stock Balance

Real-time stock balance reports show how much raw material, mixture, sheets, and finished plates are available at any moment.

🏭 How the Paper Plate Manufacturing Process Works

Below is a real-world scenario that shows how a paper plate manufacturing unit operates — and how our ERP helps manage every stage efficiently.

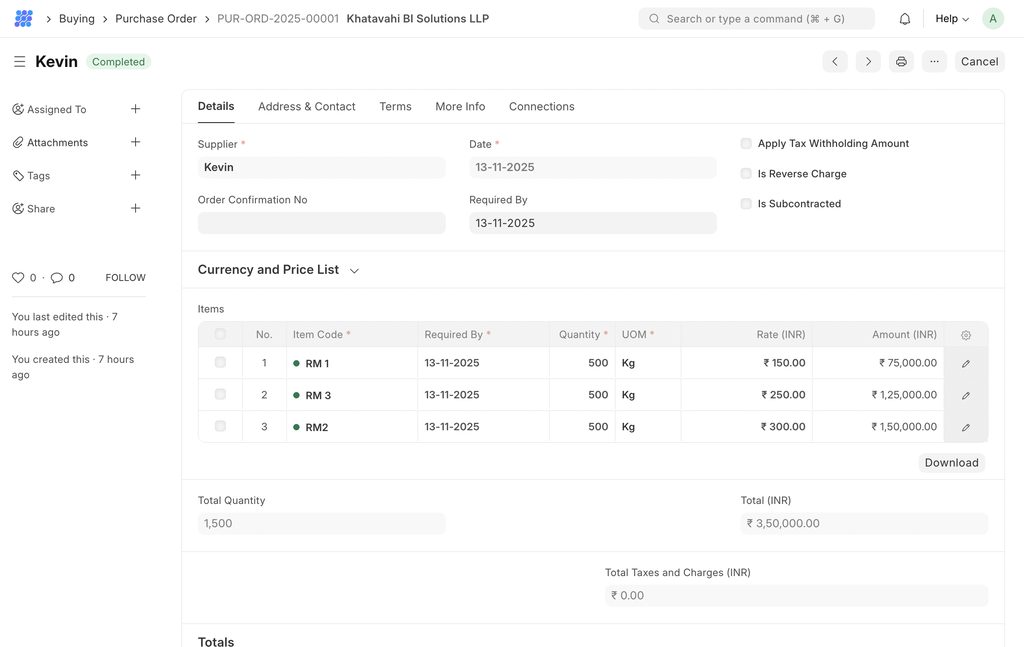

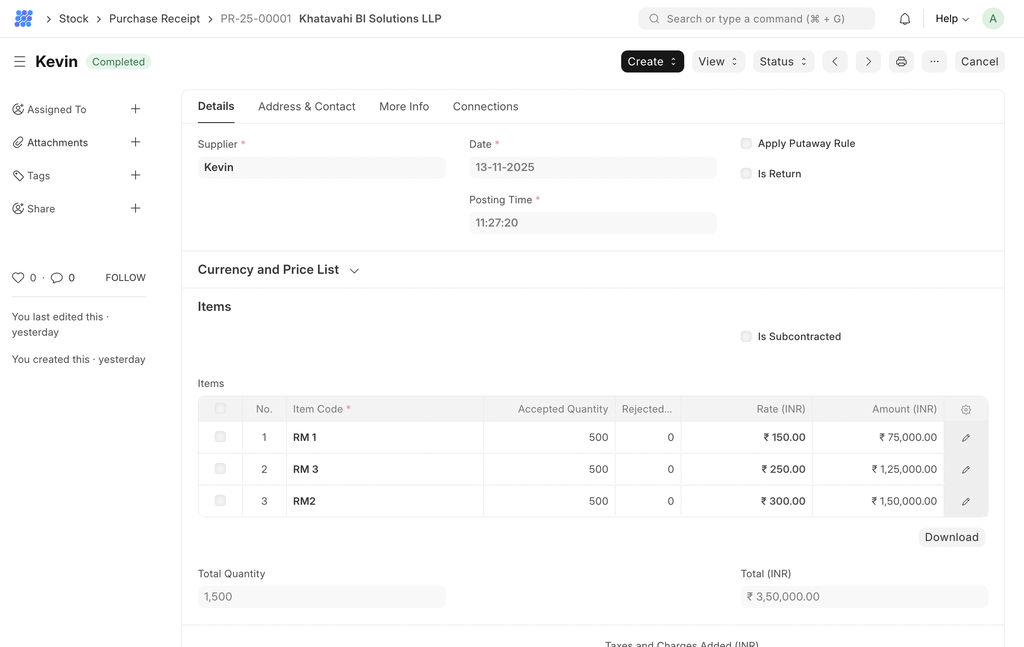

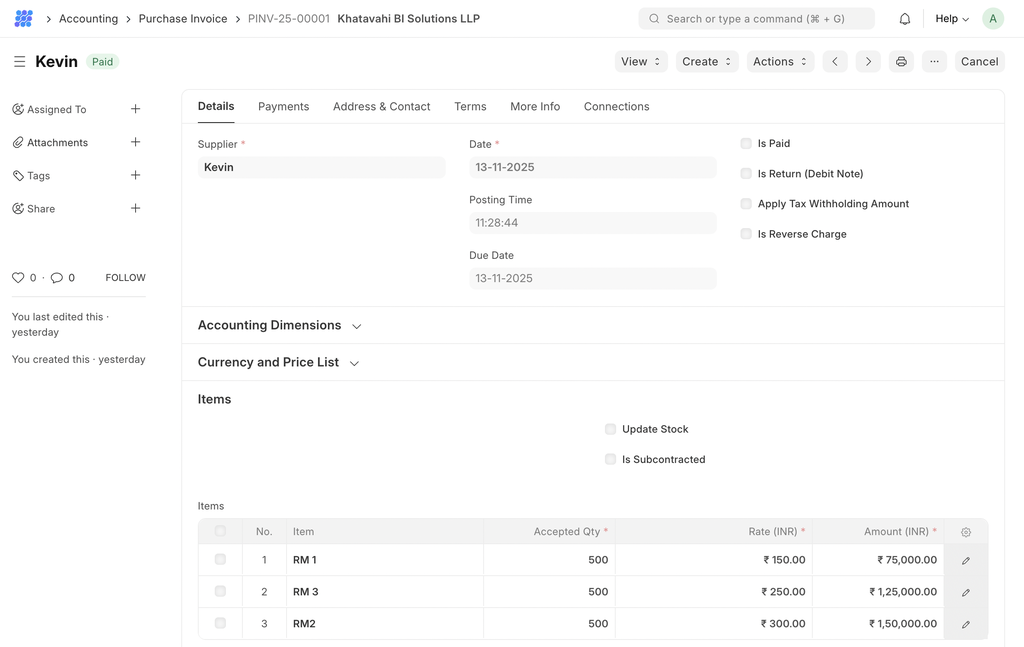

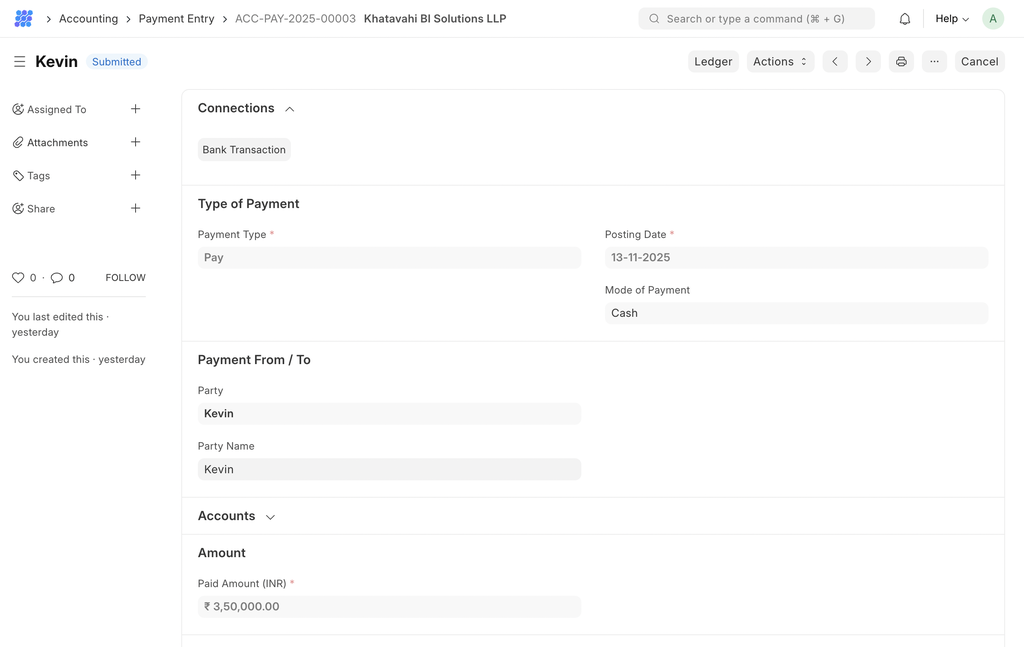

Step 1: Procuring Raw Materials

A typical manufacturing cycle starts with the purchase of three primary raw materials: RM1, RM2, and RM3. Each material has different suppliers, pricing, and stock units.

When raw materials are purchased, the ERP automatically logs:

Purchase Cycle

- Request for Quotation

- Supplier

- Supplier Quotation

- Purchase Order

- Purchase Receipt

- Purchase Invoice

- Payment Entry

After these steps, stock levels of RM1, RM2, and RM3 are instantly updated, giving managers accurate visibility.

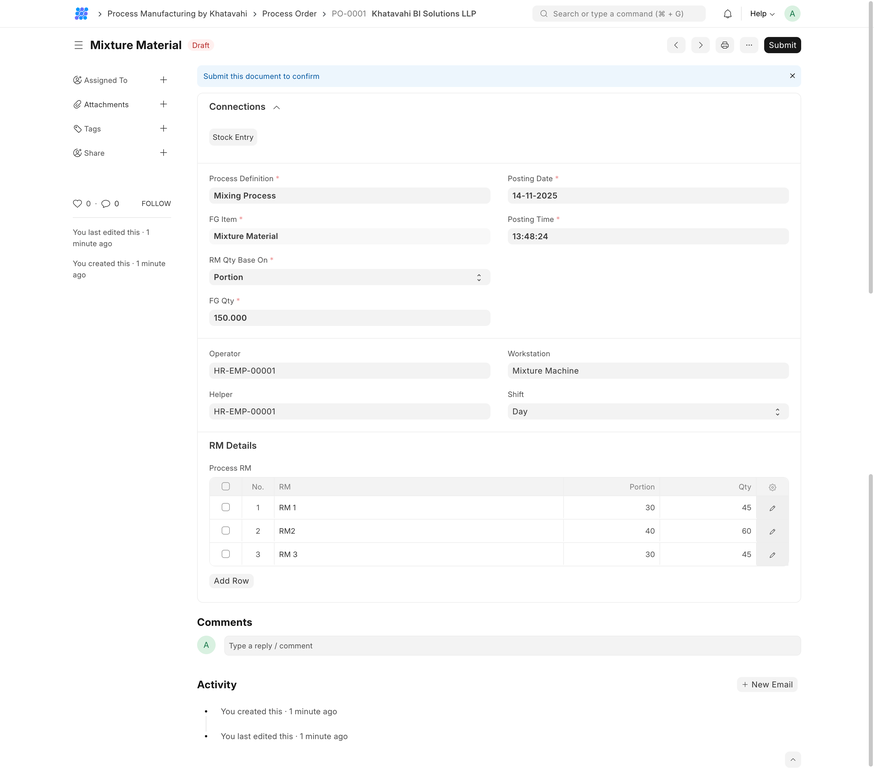

Step 2: Preparing the Mixture

After the raw materials arrive, the production team prepares a Mixture Batch by combining RM1, RM2, and RM3 in a specific ratio (e.g., 40% RM1 + 35% RM2 + 25% RM3).

In the ERP:

- A Mixture Entry is created with the quantity of each raw material used.

- The system automatically reduces the corresponding stock from the warehouse.

- The final “Mixture Material” becomes a new semi-finished inventory item ready for the next process.

This ensures accurate material tracking and cost calculation for every batch.

Process Definition for Mixture Bulding

Process Order

Stock Balance after Process Order Submit

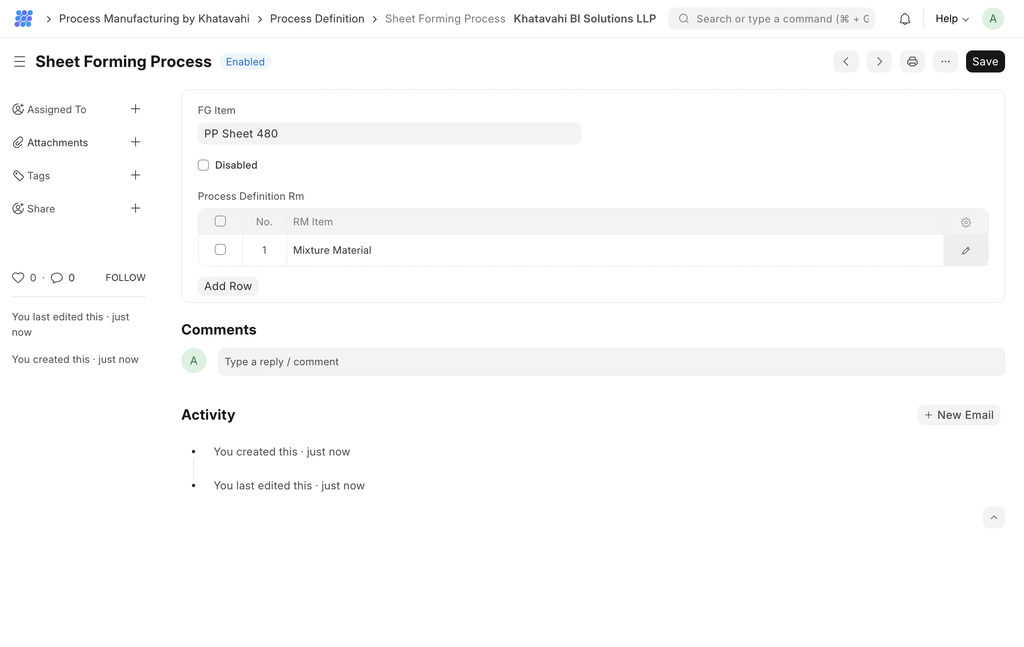

Step 3: Sheet Formation

The prepared mixture is now sent to the Sheet Forming Machine. Here, it’s converted into Sheets, which will later become the final food plates.

In the ERP, a Production Order is generated for the sheet-making process. It records:

- The machine used

- Operator details

- Number of sheets produced

- Wastage percentage

This helps monitor machine performance and production efficiency.

Process Definition for Sheet Manufacturing

Process Order for sheets

Stock Balanse After Sheet Manufacturing

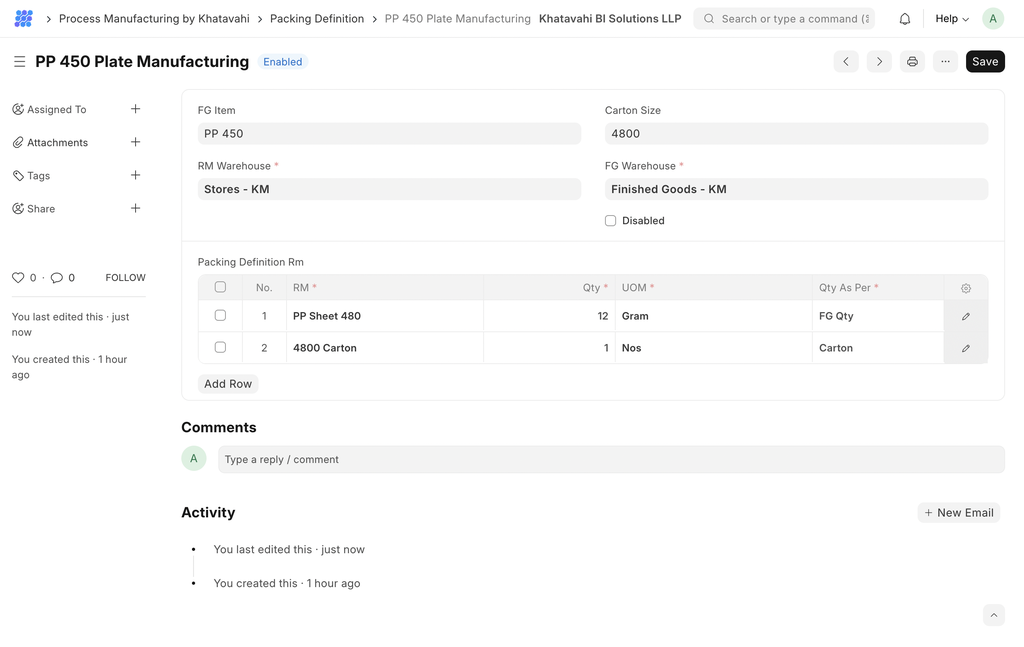

Step 4: Plate Manufacturing

Finally, the sheets are transferred to the Plate Pressing Machine, where they are molded into paper food plates of various sizes (6-inch, 8-inch, 12-inch, etc.).

Each finished plate batch is recorded as a Finished Good Entry in the ERP. The system automatically: • Moves the stock from “Sheet” to “Finished Plate” inventory • Calculates material consumption • Updates available finished stock in real time

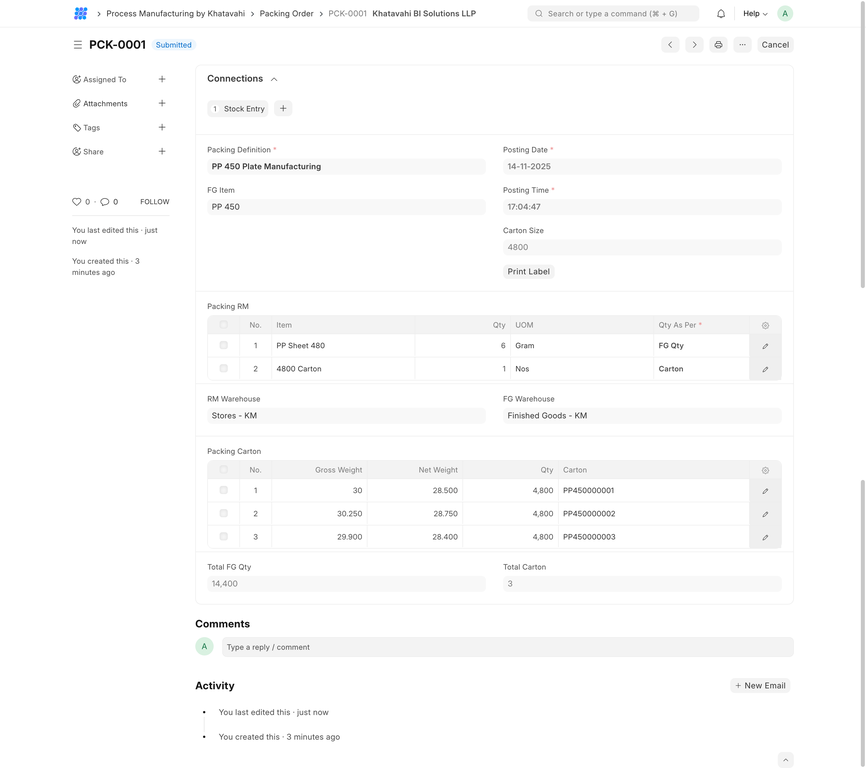

Packing Definition

Packing Order

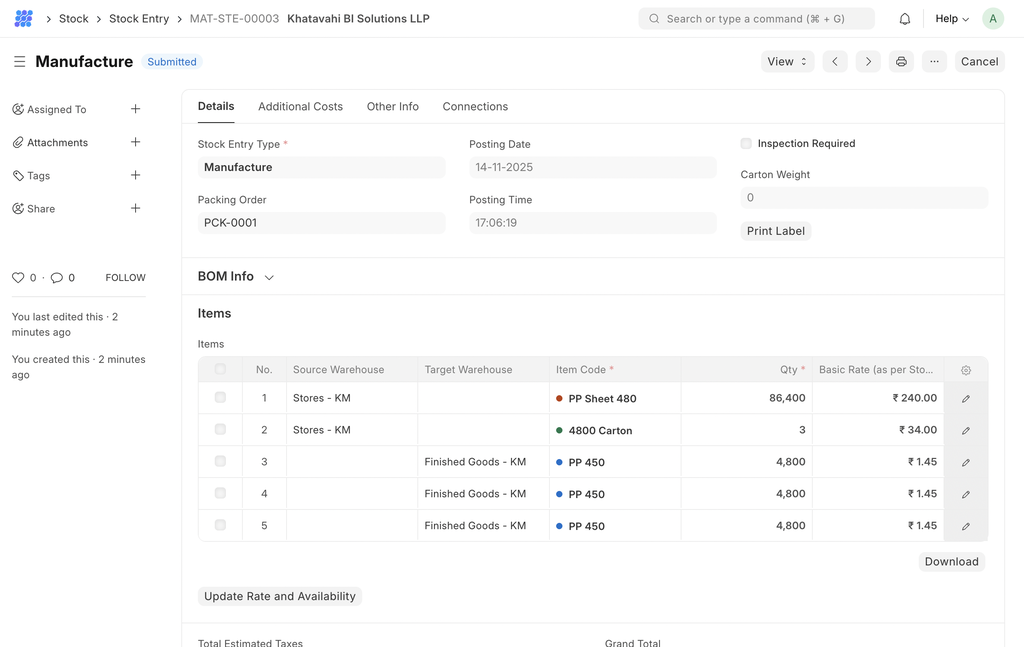

Automated Manufacturing Stock Entry for Packing Order

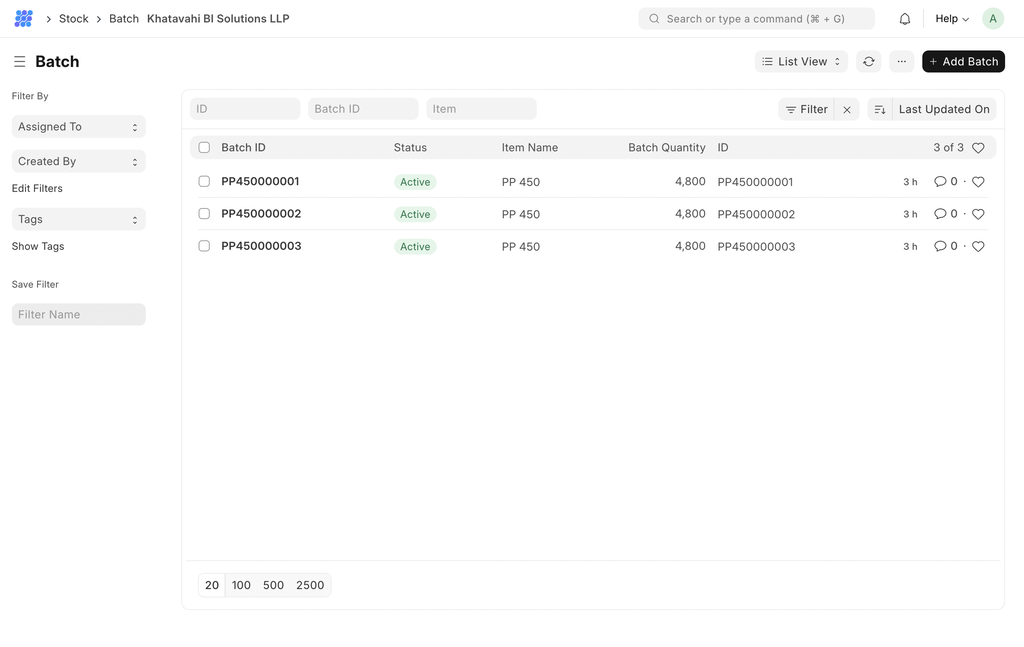

Carton Master (Batch)

Carton Barcode Label

📊 Complete Visibility from Start to Finish

By the end of this cycle, the ERP provides a clear picture: • How much of each raw material (RM1, RM2, RM3) was consumed • Total mixture and sheets produced • Wastage and yield percentage • Final quantity of finished paper plates ready for dispatch

All this happens without manual calculations or paperwork — the ERP manages it automatically.

Click Here to Schedule Demo

No Spam Policy

We respect your privacy — no spam, no unwanted emails, ever. You’ll only hear from us regarding your inquiry, demo scheduling, or genuinely helpful resources related to manufacturing ERP. Your information is safe and will never be shared with third parties.

Jigar Tarpara

ERPNext & Frappe Consultant ERPNext & Frappe Developer CEO at Khatavahi BI Solutions LLP

No comments yet. Login to start a new discussion Start a new discussion